News

Foundation Model for Humanoid Robots and Major Isaac Robotics Platform Update

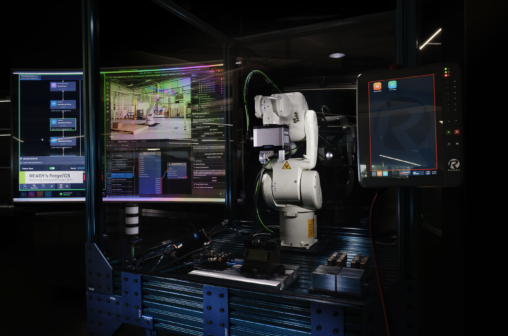

Isaac Robotics Platform Now Provides Developers New Robot Training Simulator, Jetson Thor Robot Computer, Generative AI Foundation Models, and CUDA-Accelerated Perception and Manipulation Libraries

NVIDIA today announced Project GR00T, a general-purpose foundation model for humanoid robots, designed to further its work driving breakthroughs in robotics and embodied AI.

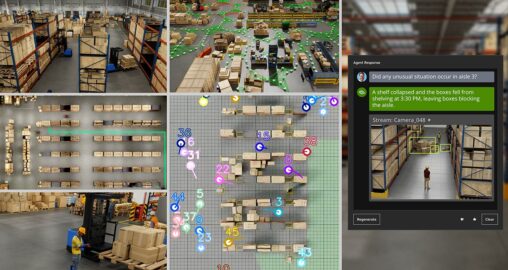

NVIDIA software — Omniverse, Metropolis, Isaac and cuOpt — combine to create an AI gym where robots, AI agents can work out and be evaluated in complex industrial spaces. Learn more about the latest advancements in generative AI and industrial digitalization at NVIDIA GTC, a global AI conference running through Thursday, March 21, at the San Jose Convention Center and online.

magazin Mehatronika and NVIDIA support Pupin’s Challenge 2023 — a regional young makers’ competition

Mehatronika’s team was also present during the competition and further helped with press coverage and event organization. We’d like to thank our friends at NVIDIA for helping us further motivate future engineers, and finally, the organizers of Pupin’s Challenge for gathering so many passionate young people and providing them with a friendly, competitive environment.

Magazin Mehatronika, with support from NVIDIA is giving away two Jetson Nano Developer kits.

The Jetson Nano is a small edge AI system made by NVIDIA, perfect for students, makers and educators.

Powerful enough for computer vision applications, the Jetson Nano supports external cameras, enabling powerful projects, aware of their surroundings.

Since the Jetson Nano itself is a module, with a reference carrier board in the kit, it’s possible to integrate it into custom end solutions. This level of flexibility is required for industry usage, as well as more serious projects.

More information, and the giveaway submission form can be found at the following link.

Saildrone is making a splash in autonomous oceanic monitoring.

The startup’s nautical data collection technology has tracked hurricanes up close in the North Atlantic, discovered a 3,200-foot underwater mountain in the Pacific Ocean and begun to help map the entirety of the world’s ocean floor.

Based in the San Francisco Bay Area, the company develops autonomous uncrewed surface vehicles (USVs) that carry a wide range of sensors. Its data streams are processed on NVIDIA Jetson modules for AI at the edge and are being optimized in prototypes with the NVIDIA DeepStream software development kit for intelligent video analytics.

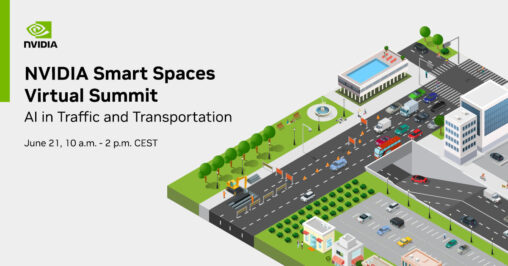

AI-powered spaces are no longer just a vision of the future. They’ve arrived in today’s streets, stadiums, cities and public transport hubs — and they can be used across industries and applications.

NVIDIA is hosting a deep dive into this topic at its inaugural Smart Spaces Summit, focused on AI-powered innovations within traffic and transportation. The virtual event takes place Wednesday, June 21, from 10 a.m. to 2 p.m. CEST.

At COMPUTEX 2023, NVIDIA announced the new Jetson AGX Orin Industrial module, which brings the next level of computing to harsh environments. This new module extends the capabilities of the previous-generation NVIDIA Jetson AGX Xavier Industrial and the commercial Jetson AGX Orin modules, by bringing server-class performance to ruggedized systems.

NVIDIA’s GTC 2023 keynote has just ended, with GTC itself ending on March the 23rd – which means an array of exciting new industrial announcements just went live. You can always watch the full keynote at the following link, but we’ve also curated a selection – which you can find in this article – of the most important announcements given during the event.

The LattePanda Team launched the world’s thinnest pocket-sized hackable computer – LattePanda 3 Delta with global electronic components distributors. The collaboration will ensure that the product choice for LattePanda 3 Delta is passed on to customers through quick, easy online selection via the website of global electronic components distributors and LattePanda.

“LattePanda Team is so proud to cooperate with the global electronic components distributors for this joint launch. It delivers an exciting message to our customers that they can gain fast, easy access to our high-performance and hackable LattePanda 3 Delta anywhere in the world. Our collaboration will assure even higher levels of customer service,” said Sandy Zhang, CMO of LattePanda Team.

LattePanda 3 Delta is poised to define a new era of computing and drive mega creativity for tech enthusiasts and industry innovations. It gets a significant performance boost by upgrading from the Celeron

N4100 of the LattePanda Delta to the Intel 11th-generation Celeron N5105 processor with up to 2.9GHz burst frequency, maintaining almost the same pinout and layout as the previous version to allow for effortless system migration or upgrading by replacement. Compared to its previou version, the CPU of LattePanda 3 Delta speeds up to 2 x faster while the GPU speeds up to 3 x faster to support usage like playing a 4K HDR video and running heavy games.

For over a century, Okuma, has been developing grinding machines for the highest quality demands. Though a lot has changed since the beginning, some aspects remain the same. Okuma CNC grinders still achieve their high precision, productivity and longevity due to a symbiosis of craftsmanship and state-of-the-art technologies.

Achieving supreme quality while maintaining high productivity is difficult for most manufacturers. Measures to improve the outcome often slow down machining processes. In order to combine the two partly conflicting objectives, machine tools need not only high performance hardware but also customised software to reach the machine’s full potential.

In a new whitepaper published today, ABB reveals potential for significant energy efficiency improvements in industry and infrastructure enabled by the latest and most high-efficiency motors and variable speed drives. ABB calls on governments and industry to accelerate adoption of the technology to help combat climate change.

According to the International Energy Agency (IEA), industry accounts for 37 percent of global energy use and some 30 percent of global energy is consumed in buildings.

While mostly hidden from public view, electric motors – and the variable speed drives which optimize their operation – are embedded in almost every built environment. They power a vast range of applications fundamental to our modern way of life, from industrial pumps, fans and conveyors for manufacturing and propulsion systems for transportation to compressors for electrical appliances and heating, ventilation and air conditioning systems in buildings.

The pneumatically actuated robot quick-change system SCHUNK SWS-046 allows fast and process-reliable change of different gripping systems and tools at the front end. With its four optional module attachment surfaces, it offers a wealth of options for supplying the connected pneumatic, hydraulic or electric effector.

The single-acting clamping module SCHUNK VERO-S NSE3 138-V4 increases the flexibility in clamping pallets with just one clamping pin: While the pallet alignment on conventional single clamping modules, which are equipped with an anti-twist protection is precisely defined, pallets on the VERO-S NSE3 138-V4 can be rotated in 90° increments.

A robot hand carefully grips a randomly assembled formation of colorful toy blocks and then puts it down. Identify, grip, put down. Over and over again. What at first glance appears to be a childlike game is actually extremely sophisticated: Tomorrow’s robots and handling systems will be able to identify and examine objects on their own and ultimately handle them autonomously. At Hannover Messe, gripping system and clamping technology specialist SCHUNK will be demonstrating the possibilities and opportunities that intelligent gripping system solutions offer smart factories as well as how digitalization and artificial intelligence enhance handling processes.

Producing a variety of beverages in glass and PET bottles, cans and cartons, PepsiCo partner SMLC is Lebanon’s biggest beverage bottling company. The implementation of a line management system based on zenon software from COPA-DATA put an end to manual data entry, providing comprehensive information for efficient filling operations

Elesa+Ganter has long been market leader also in the use of reinforced technopolymer (SUPER-Technopolymer) for robust industrial applications and specialised environments, among the other metal materials.

SUPER-Technopolymers represent the most recent and advanced development in engineering of polymeric materials. Thanks to the presence of high percentages of glass fibre linked to the base polymer with suitable primers and / or the presence of aramid synthetic fibre, SUPER-Technopolymers are characterized by mechanical and thermal properties far superior to the traditional polymers.

The main focus of Konelek is manufacture of ground equipment for maintenance of passenger planes and jet engines, development of unmanned aerial vehicles and Design Organization Approval (DOA).

“CATIA has been the standard for mechanical design in the aerospace industry for decades. It is used by all leading manufacturers, including some of our end customers. Konelek follows that standard and implements the CATIA software solution in all its development and production projects, including the most advanced activities such as 5-axis CNC machining and 5-axis machining simulation.” – Andrija Ekmedzic, Director

Task

Konelek was looking for a CAM (computer-aided manufacturing) solution, which would, in combination with the existing CATIA design software, improve the manufacturing process.

CADCAM Data, as an experienced company in precise mapping of customer requirements and implementation of sophisticated industrial solutions, has gained the trust of Konelek, and then the task to fully engage in development and production processes to make concrete proposals for business improvement through the segment of multi-axis CNC programming.

With the professional support of CADCAM Data engineers, it was decided to continue working on the CATIA software solution since it best responded to all the set requirements for further improvement of business processes. Konelek was looking for a CAM (computer-aided manufacturing) solution, which would, in combination with the existing CATIA design software, improve the manufacturing process.