Dymo has truly pushed the market forward with their Rhino 5200 industrial label printer, creating a robust and durable handheld that creates labels with those same qualities.

Pros

- High print quality

- Long battery life

- Robust and durable

Cons

- Pricey

- Some minor firmware bugs

There are many things in industry that simply need to be labelled – panels, cables, storage systems, or just general things. Label makers are small thermal transfer printers that enable high-quality labels to be made on-site, and perhaps there is no better known brand than Dymo.

Today, we’re glad to have our hands on one of the most popular labellers of this type – the Dymo Rhino 5200, a successor of the best-selling, industry-standard RhinoPro 5000. This review unit was sent to us by Dymo’s Serbian distributor – Eurocom International d.o.o.

The kit comes with two vinyl tapes – a 12mm and a 19mm one, a nice quick reference booklet, a Li-ion battery pack, a charger, and finally, the Rhino 5200 itself. This all comes in a nice, hard plastic carrying case with a satisfying locking mechanism. The case feels durable, so no complaints there.

Onto the unit itself – it’s quite a chunky device and is very solidly built. It bears Dymo’s signature black-on-yellow colour scheme, with an integrated rubber holster that protects it from the wear-and-tear out on the terrain. The selection of printing tapes is also impressive, ranging from standard paper tape to vinyl, nylon, heat-shrink tubing and polyester. These tapes are all tested to withstand the elements, from UV and heat exposure to extreme cold and rain.

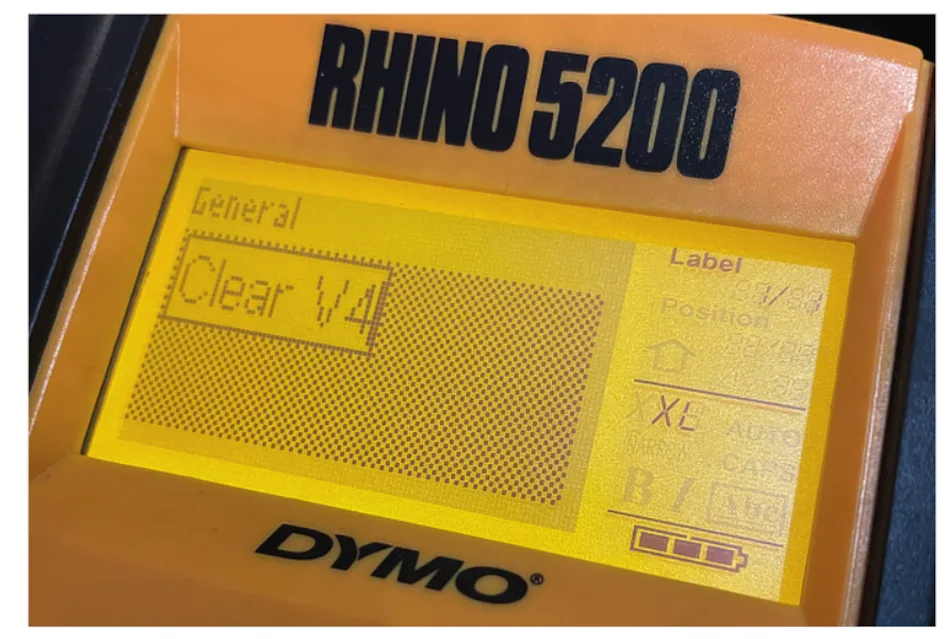

The Rhino 5200 is a label-making powerhouse, capable of making many different kinds of labels, including general-purpose horizontal and vertical labels, wire wraps and flags, electronics modules, blocks and panels. Each of these modes is available with one press (some require a shift-press) of a dedicated button. This brings up the setup wizard for these modes, allowing for quick setup of even the most complicated label types.

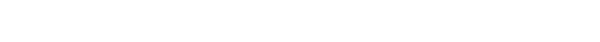

The Rhino 5200 can also auto-scale text, so fixed length labels are also possible. It’s easy to dial in an exact length you require and let the Rhino do font size adjustments. This also applies to other modes, where you can type in exact port-to-port distance, module configuration or patch panel dimensions. There’s also support for more than 1 line of text (3 lines for 12mm, 5 lines for 19mm tapes and 2 lines for smaller tapes), as well as an extensive library of symbols that can be printed, ranging from electronics symbols to hazard and miscellaneous pictograms.

Labeling wires is also a breeze, with the only parameter needed being the wire thickness, and of course, the type of label you want. This makes this usually daunting job complete in a few quick button presses.

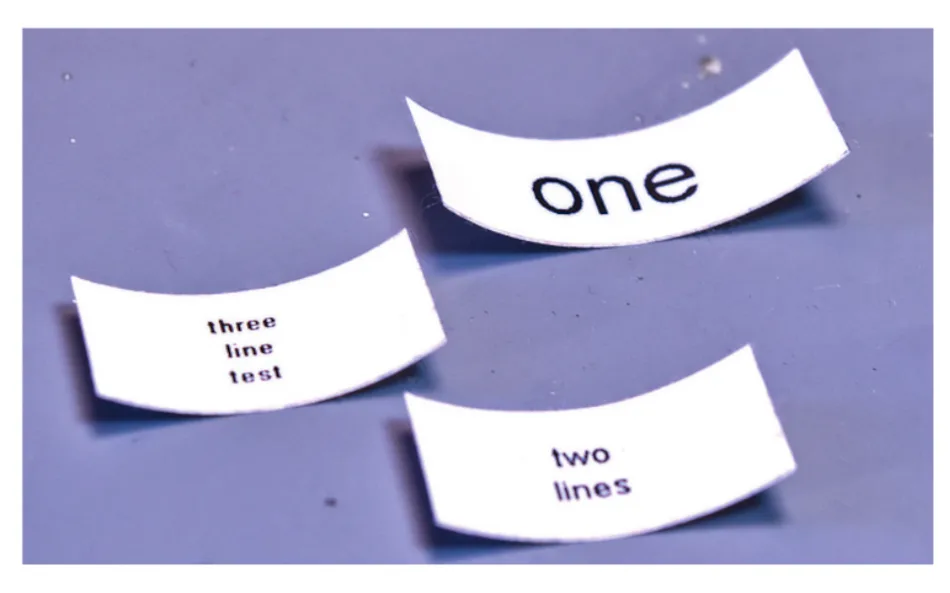

The display of the device is a monochromatic dot-matrix type display with a secondary composite segmented display on its right, for annunciators and other settings. There’s quite a lot of choice when it comes to styling your label – two fonts to choose from, several formatting options and 6 font sizes. The text editor interface is also quite intuitive – occupying the aforementioned dot-matrix portion of the screen. It’s almost a WYSIWYG editor, with support for multiple lines of text. This is a welcome change from some previous Rhino models, as well as many competitors’ models.

There’s also the ever-important print contrast adjustment setting (some materials might require higher contrast for better print quality), as well as a somewhat hidden menu (accessed by powering the device on while holding the “8” key) for adjusting print head energy, which can help with weak contrast on vinyl tapes that the standard contrast setting won’t fix.

The tape mechanism is sturdy and behind a large door on the back. The tapes are easy enough to switch, and there’s even a little brush in this compartment for cleaning the print head should it ever require that. There’s also an optical window allowing for checking tape details without opening the hatch. Batteries live under a different hatch on the back. The Dymo uses a Li-ion battery, but can also rely on six AA batteries as a backup, as well. This is an extremely handy feature in case charging isn’t an option.

Talking about batteries, the provided Li-ion battery is a quite long lasting. The initial charge took about 7 hours, and subsequent charges took only about 2, but we got over a week of testing and printing with the device on one single charge.

The vinyl labels we had are all made of quality material that is hard to tear, sticks strongly even to challenging surfaces, and peels offwithout leaving any trace. The few labels that did leave a trace had their leftover adhesive easily wiped offwith some 94% IPA or 70% ethanol. We also submerged a few of these labels underwater for prolonged amounts of time, as well as mildly corrosive and caustic substances, and they held were chemically and physically unchanged after several days in tough conditions.

Being a thermal transfer printer, this also means that labels won’t darken or fade should the ambient temperature go into extremes – in fact, we blasted these labels with a 90 degree Celsius air stream and they remained unchanged – meaning that even heat-generating PCBs or components can be safely labelled with these.

The Rhino 5200 also has some truly advanced features, such as label serialisation, which offers a modular, character-by-character approach to this feature. The two modes – simple and advanced serialisation offer varying levels of complexity during setup, but also varying levels of control.

There’s also the barcode option, which allows for printing of different kinds of barcodes on the 19mm label.That being said, everything we’ve labelled with the Rhino 5200 came out absolutely perfect, and it was a joy to work with. We have to say that it’s one powerful tool capable of much more than initially meets the eye.

There is one tiny thing we’d like to note. In our testing, we’ve found it absolutely necessary to power offthe device before changing tapes, otherwise there is a chance that the print head won’t align properly with the middle of the ribbon. This is nothing major, but we’d just like to point a minor oversight in the provided documentation.

Overall, the Dymo Rhino 5200 is an extremely well-built, industrial quality label printer that’s up to any task, from general labelling and barcode printing to wire labels, and that consistently delivers. The tapes are also pretty long – 5.5m for about $15 a piece, and the entire kit costs about $350, depending on the place of purchase. This makes it a very enticing option for those looking to organise their factory floor, lab, workshop or projects with a portable, reliable little machine.

More informations: Eurocom international d.o.o.

Batajnički Drum 211B 11185 Zemun/Beograd – SRBIJA

tel: +381 11 4155-000 https://www.eurocom-bg.rs